High-strength ductile iron manhole cover

Made of special ductile iron material, processed through precision casting technology, it has extremely high compressive and impact resistance.

Key words:

Classification:

Product Details

Model

EN124-C250

Specification

850×622×100

Product Advantages

High strength and high toughness:Ductile iron undergoes a unique spheroidization treatment process, transforming the graphite form from flake to spherical, significantly improving the material's tensile strength, yield strength, and elongation. Its performance is close to or even exceeds that of certain carbon steels, allowing it to withstand considerable pressure and impact loads.

Excellent corrosion resistance:The alloying elements (such as chromium, nickel, molybdenum, etc.) added to ductile iron effectively enhance the material's corrosion resistance, allowing it to be used for long periods in various harsh environments without damage. The surface can also undergo anti-corrosion treatment to further enhance its corrosion resistance.

Good machinability:Ductile iron not only has excellent mechanical properties but also maintains good machinability, making it easy to cut, drill, weld, and perform other subsequent processing, meeting the needs of different application scenarios.

Economical and environmentally friendly:Compared to steel, ductile iron, with its excellent corrosion resistance, also reduces energy consumption and maintenance costs during operation, aligning with the current trend of green and low-carbon development.

Production Process

Our company adopts the ductile iron production process to ensure stable and reliable product quality. The specific process flow is as follows:

Raw Material Preparation:Select high-quality pig iron, scrap steel, and other raw materials, and equip with rare earth magnesium alloys and other spheroidizing agents and inoculants.

Melting and spheroidization treatment:At high temperatures, the raw materials are melted into molten iron, and spheroidizing agents are added for chemical reactions, transforming the graphite form from flake to spherical. The chemical composition and temperature of the molten iron are strictly controlled to ensure spheroidization effectiveness.

Inoculation treatment:Inoculants are added to the molten iron to further refine the matrix structure, enhancing the strength and toughness of the cast iron.

Pouring and forming:The treated molten iron is poured into pre-prepared molds, forming the required castings through cooling and solidification.

Post-processing and quality control:The castings undergo cleaning, heat treatment, polishing, machining inspection, and other post-processing steps to ensure product quality meets standard requirements. Strict quality control measures are implemented, monitoring the entire process from raw material selection to finished product delivery.

OEM Customization Service

Our company provides professional OEM customization services, capable of producing various specifications of ductile iron products according to customers' specific needs and design drawings. Our customization services cover but are not limited to the following aspects:

Product design and development:Product design and development based on customer needs, providing personalized solutions.

Material selection and proportioning:Selecting suitable weights based on customer application scenarios to ensure product performance meets requirements.

Production process optimization:Optimizing the production process flow based on customer order quantities and delivery requirements to improve production efficiency and product quality.

Quality control and testing:Strict quality control and testing of customized products to ensure stable and reliable product performance.

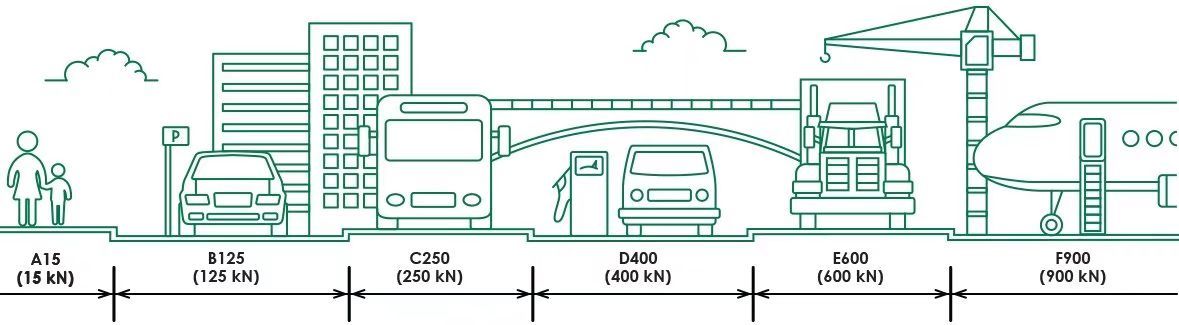

Application scenarios

Company Profile

Handan Pingxin Casting Co., Ltd. was established on September 16, 2009 with a total investment of 0.3 billion yuan. Covers an area of more than 28000 square meters. Business scope: precision casting processing, auto parts, municipal castings, ductile iron research and development, processing, sales, import and export of goods or technology.

The company has 160 employees, including 6 high-grade technology, 8 intermediate professionals, 2019-2024 period, a total of 22 utility model patents.

Adhering to the concept of "survival by quality and development by reputation", the company is well received by customers. Based on the belief of green, environmental protection and innovation, the company is based on opening up domestic and foreign markets, and its products sell well in more than 20 countries and regions such as Europe and America.

Certificate of Honor

EIA has complete sewage discharge procedures, stable production standard machinery level 3 enterprises, passed the ISO9000 quality management department system certification, 14001 environmental management system certification, 18001 occupational health management system certification, and won the national credit unit, AAA credit unit, AAA quality service credit unit, AAA contract and credit unit, China foundry industry qualification level 1, Hebei province outstanding technology enterprise and other honorary certificates.

Recommend Products

Immediate consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!

Precision casting processing, auto parts, municipal castings, ductile iron research and development, processing

Contact Us

Address: South District of Economic Development Zone, Jize County, Handan City, Hebei Province

Quick Navigation

Enterprise concept

Based on the belief of green, environmental protection and innovation, the company is based on opening up domestic